- Production Technology

- COSMAX NBT’s Own Specialized Production Line

(Exclusive Production Line for Probiotics)

Industry's first production line dedicated to lactobacillus

Increased viability of strains and reduced customer cost through optimized temperature / humidity control for each strain

Control of temperature and water activity, the key factor of probiotics production

· Control the temperature of 20±5℃ and humidity of RH 30% or less by establishing a dedicated line · Establishment of temperature and humidity optimization control system that is not affected by seasons or climate · Recording and controlling temperature and humidity daily · Study of changes in strains depending on production conditions (accumulation of data)

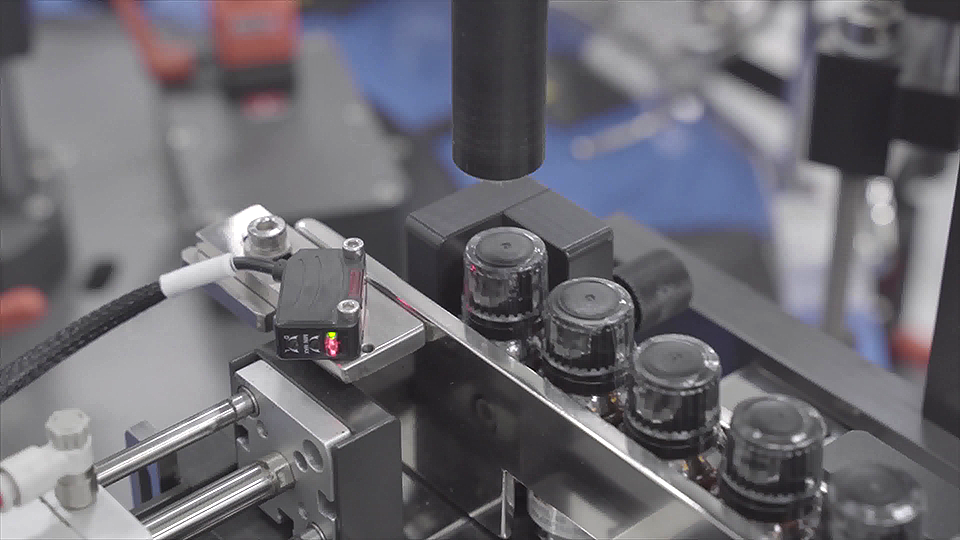

[Temperature / Humidity Control System]

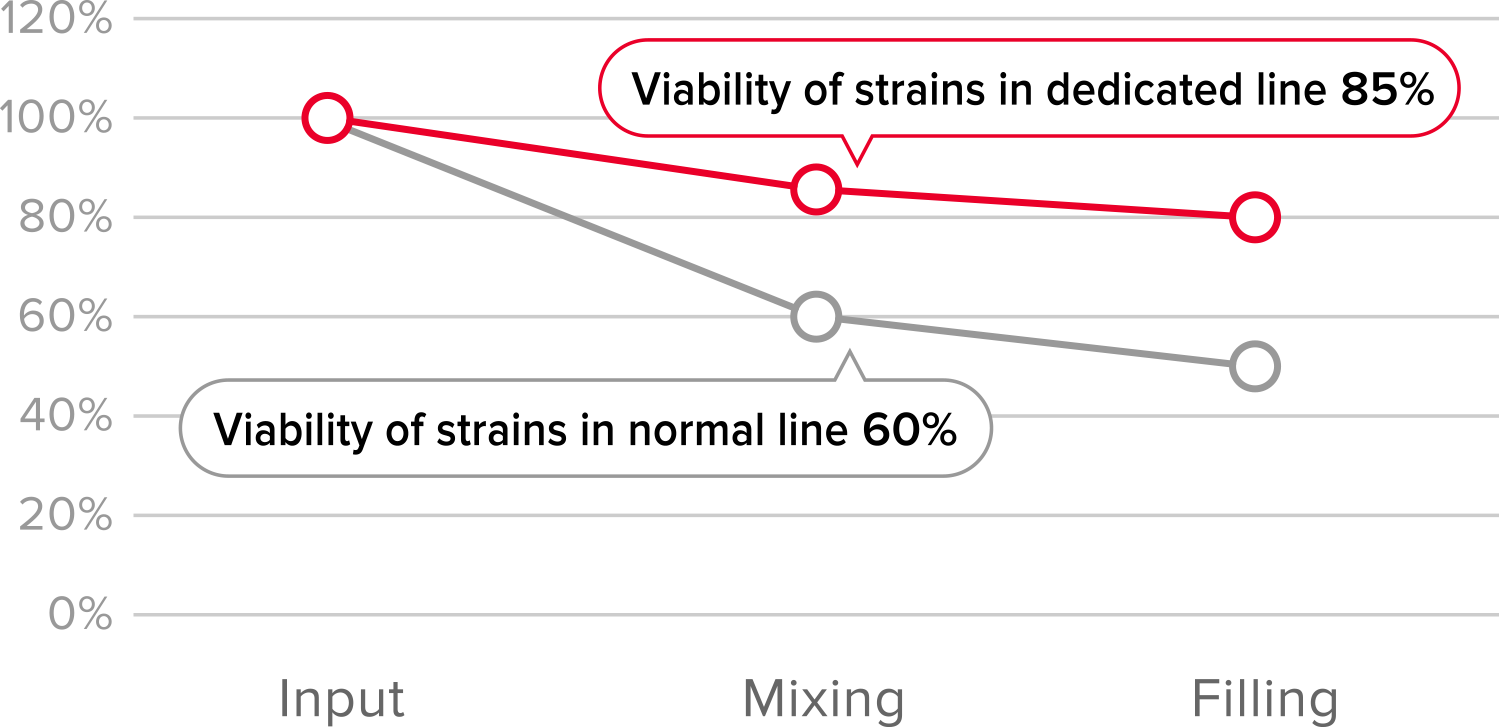

[Comparison of Viability of Lactobacillus: EPP Line vs. Normal Line]

Micro Emulsion Technology of oil-soluble ingredients

Improving absorption of oil-soluble and poorly soluble ingredients and implementing various dosage forms

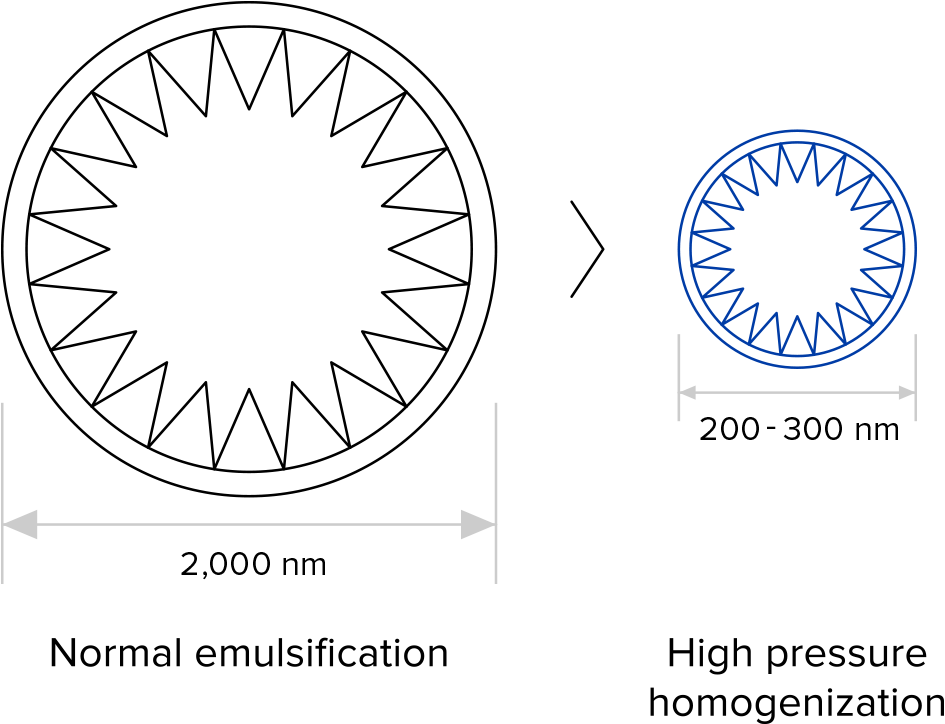

Technology that increases bioavailability by passing a highly pressurized fluid through a homogenizer valve to reduce particle size by atomization, emulsification, dispersion, etc.

· Diversifying formulations of oil-soluble and poorly soluble raw ingredient (liquid types such as gummy, jelly, etc.) · High bioavailability expected with fine particles · Expanded categories and mass-production possible

For nutritional supplements

· Vitamin A

· Vitamin D

Diet / Inner Beauty

· CLA (Conjugated Linoleic Acid)

· GLA (Gamma Linoleic Acid)

Immune & Antibacterial

· Co-Q10

· Turmeric

· Omega 3

· Propolis

Fatigue overcoming

· Royal Jelly

· Octacosanol

· Milk Thistle

Eye health

· Lutein

· Hematococcus

Memory · Phosphatidylserine

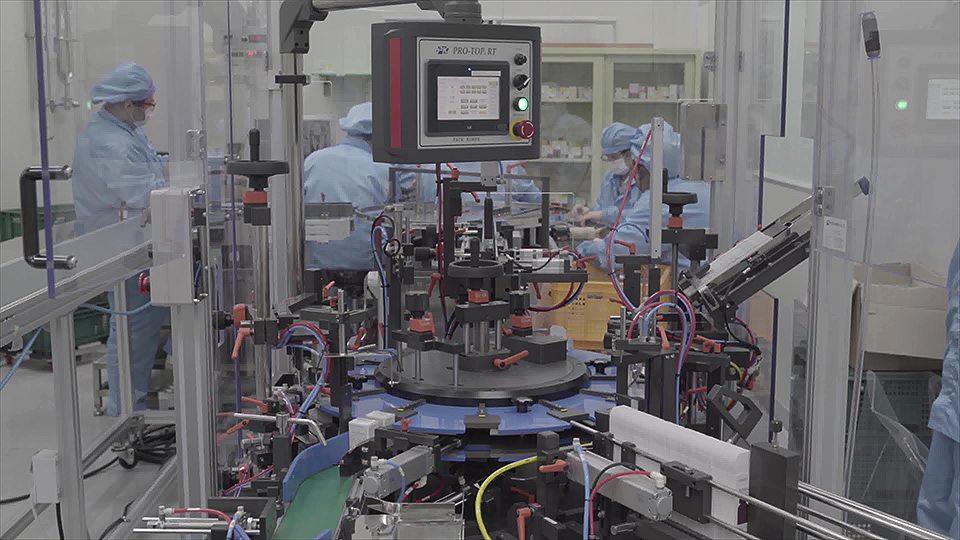

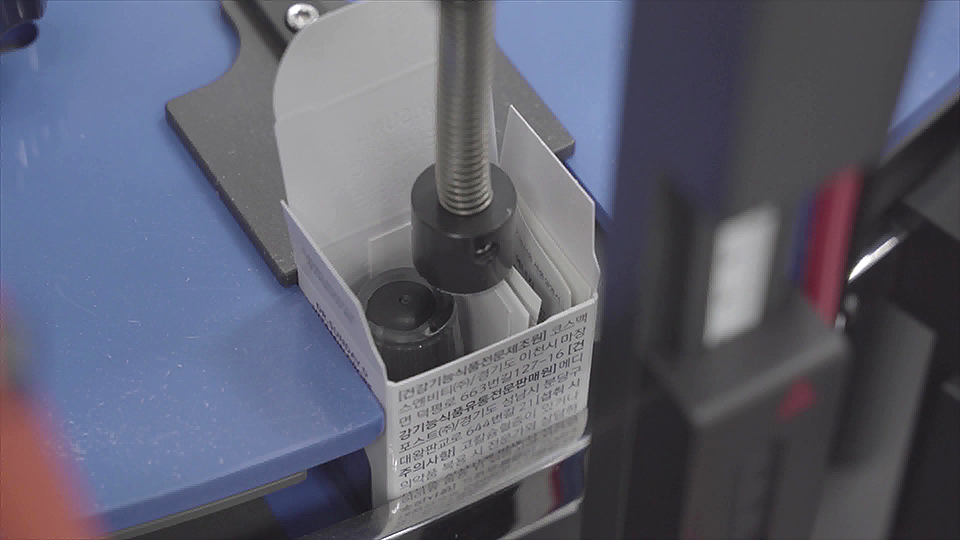

Small Bottle Automatic Line

Introduction of small bottle automatic charger

→ Quality improvement: mitigating quality risks→ Reduce airlift and increase productivity

※ Reduced man-hours by ½

Reject E-mail Collecting

The COSMAX NBT website prevents and does not allow any act or attempt to collect e-mail addresses present in this website by programs for collecting e-mail addresses or by other technical means without our prior approval. Be advised that any violation of this provision may result in criminal penalties in accordance with the Information Network Act.